Together with regenerative material scientists Circular Systems, we are exploring ways to incorporate their ‘waste-to-fiber’ technology into our products. In 2022, we have been trialling their Agraloop™ BioFibre™ technology, a natural fiber that is refined from food and medicine crop left-overs such oilseed hemp, CBD hemp, oilseed flax, banana tree trunk, and pineapple leaves.

WASTE IS A HUGE PROBLEM

Left-overs from food and medicine crops are sometimes burned, left to rot, or used in low-value industrial applications.

What is the science behind Agraloop™ fibers? These fibers are made by refining the crop left-overs (residue) into a high-value new natural textile grade fiber.

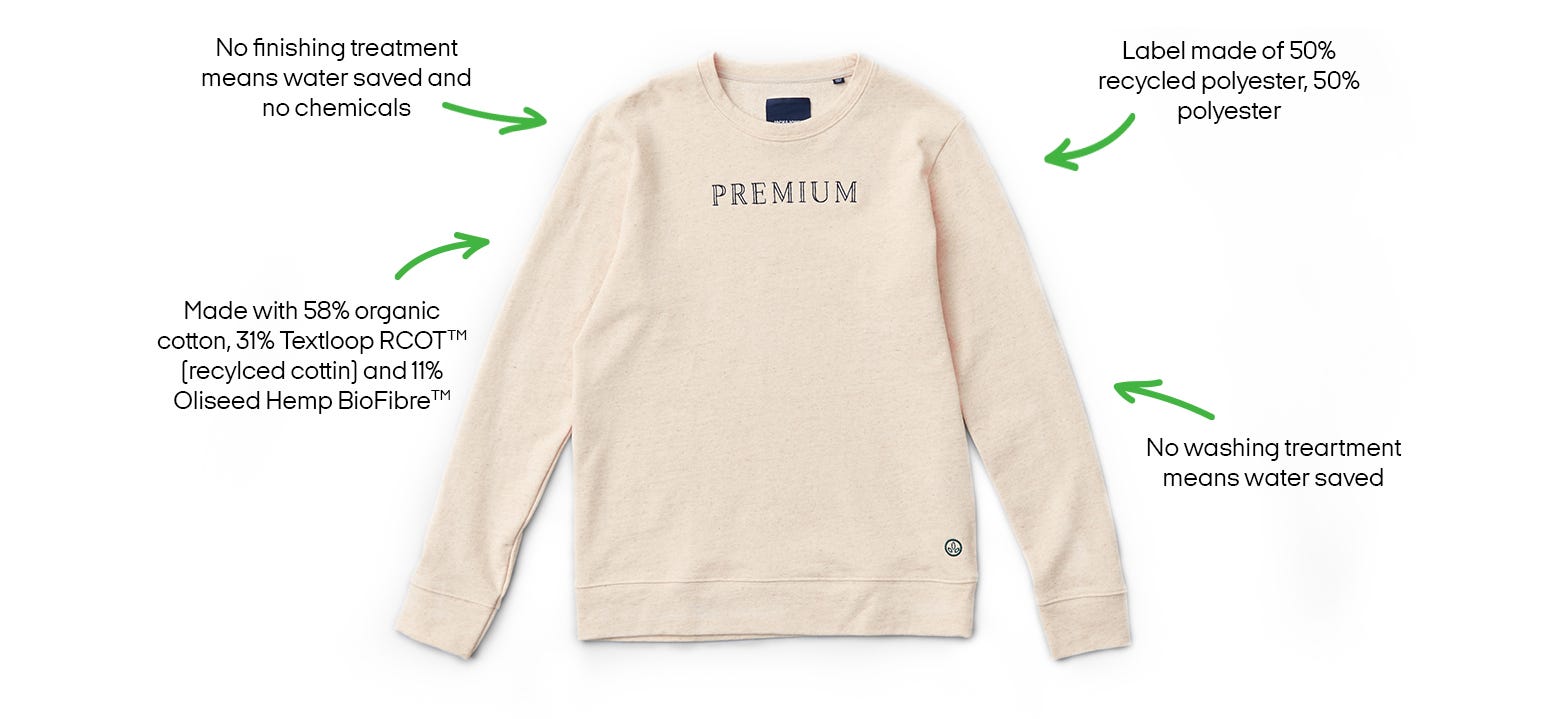

The Agraloop™ Hemp BioFibre™ is derived from oilseed hemp agricultural crop leftovers. Why oilseed hemp? It promotes multi-purpose cropping while using no harmful chemicals and supports regenerative farming practices. In addition, the crop is mainly rain-fed and has, therefore, a reduced water consumption.

Agraloop™ BioFibre™ is a low-impact, natural fiber that can reduce the dependency on fiber like cotton and polyester in most applications. It is applicable for knit and woven textiles in clothing, footwear, and accessories. Agraloop™ BioFibre™ is breathable, durable, and has inherent thermodynamic properties making it a highly versatile sustainable material solution.

For 2024, we currently trial to incorporate the Agraloop™ BioFibre™ into jeans and tees. Stay tuned for exciting product launches

ENVIRONMENTAL AND SOCIAL BENEFITS ARE

• Rainfed Crop (Non-Irrigated)

• CO2 reduction via the prevention of burning and rotting crop waste

• CO2 draw down/sequestration & phytoremediation

• Socioeconomic benefits for farming communities, transforming low value crop residue (left-overs) into high-value textile grade fiber benefitting farmers and the environment

HOW IT ALL WORKS:

1: Stalks/Stems and leaves are collected from farms.

2: The fiber is mechanically processed, extracting fiber bundles from the stalks/stems

3: With the specialized Agraloop™ wet plus dry processing technique, cellulose fiber from stems and leaves are purified into soft fiber bundles ready to spin into yarns.

4: The Agraloop™ BioFibre™ is spun with other natural fibers like Texloop RCOT™ (recycled cotton), organic cotton, and Canopy approved man-made cellulosics.