Artistic Milliners knows denim inside out. The team there has been making jeans for us in their factory in Pakistan since 2015 and they take sustainability as seriously as we do. Together, we are working to source fully traceable organic cotton through our direct-to-farm project, as well as educating and empowering our women workers through HERproject™.

We recently caught up with Managing Director Murtaza Ahmed, who gave us the lowdown on how the company is making sure it leaves a positive impact on people and the planet.

JJ: What are your day-to-day tasks at Artistic Milliners?

Murtaza: My typical day starts on the factory floor. I always tend to communicate directly with the workers in my own, informal way just to get a feel of the culture. Demands, forecasts and product needs continually change so a lot of my time is spent problem solving and being reactive – I call it ‘firefighting’!

JJ: What does social responsibility mean to you?

Murtaza: Artistic Milliners is our family business. When I joined in 2008, I had just completed my higher education in Boston. Moving back to Karachi was quite an overwhelming experience, and one thing I remember from that time is our chairman, who is also my father, telling me that we

have a responsibility to our people. As someone who is now in a managerial position, I know that we owe it to our employees to provide the best possible working conditions.

JJ: Artistic Milliners is also known for its work in gender equality. Can you tell us some more about your social responsibility practices, and your work to educate and empower women workers in particular?

Murtaza: Artistic Milliners is a Fair Trade Certified™ company, and we have SA8000® social accountability certification too. We have also been named a Sustainable Development Goal (SDG) Pioneer for our progress in gender equality and decent work. The International Finance Corporation (IFC) did a case study on the number of women we have in our company in positions of leadership, because it is not something you see often in Asia, or in the textile industry. Six of the top ten leadership positions in our company are held by women, and I can safely say that a huge part of our success and healthy bottom line is a diverse workforce. We ensure this by offering programs like childcare in our facilities, and we are even working with JACK & JONES and HERproject™ to educate our women workers on health, financial inclusion and gender equality with a digital toolkit.

JJ: How do you measure and cut down the overall carbon emissions generated by your facilities, and why is it so important to you to lower your impact?

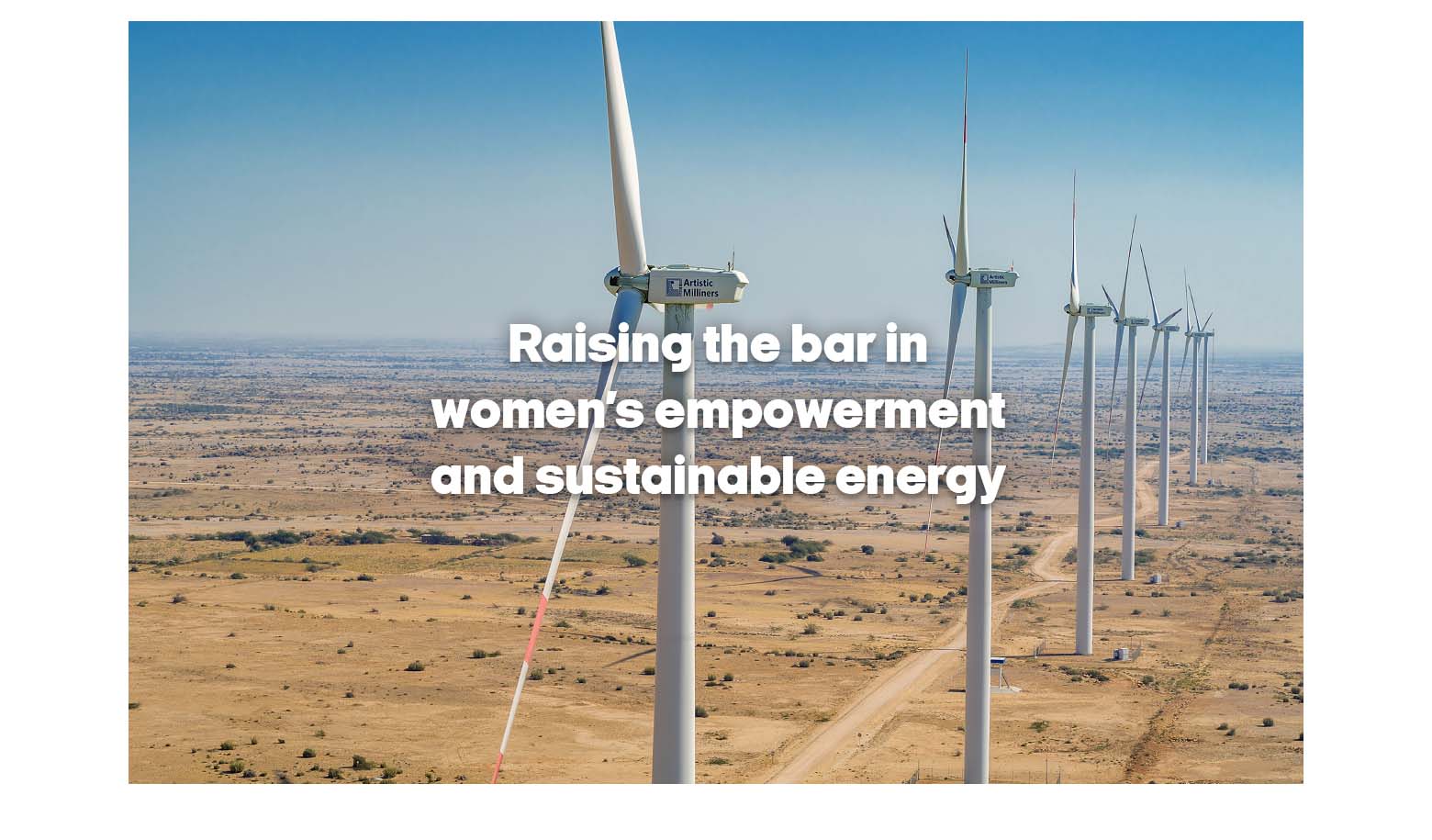

Murtaza: Climate change is a very real threat. If the sea levels rise by seven feet, Karachi will be underwater within the next 75 years. So, we have joined the United Nations Global Compact Business Ambition for 1.5C, committing to reducing our emissions to limit global warming. We are not just a textile company, but a renewable energy company too. Artistic Energy operates its own wind farm which supplies 50 megawatts of energy to the national grid, offsetting the energy we use in our facilities. We are also making investments in solar

and hydro energy, and have even put solar panels on our factories and produce around three megawatts of solar power in all our plants.

JJ: What about water? How are you working to reduce your overall usage and address the issue of water scarcity in your region head on?

Murtaza: The water basin in Karachi is depleting very, very fast. So, to ensure we are not worsening the problem, we are actively investing in water recycling. We have state-of-the-art effluent treatment plants (ETPs) which are biological, not chemical, and at the moment we recycle 85% of the treated water. We are working towards getting this up to 92%.

JJ: Are there other innovations you are using to help lower the impact of our jeans?

Murtaza: One of the things I am particularly excited about is our air-drying technology. Rather than drying a garment inside a dryer with steam that uses energy to make, we are naturally drying our jeans on conveyors which slowly rotate on the roof of our factory. I love seeing that! Another exciting project is the Milliner Cotton Initiative (MCI), which JACK & JONES and BESTSELLER have joined as part of their direct-to-farm project. With this, we are focusing on worker wellbeing in the cotton supply chain and using blockchain technology to ensure we know exactly where our fibers are coming from.

JJ: What is your

message to the global JACK & JONES brotherhood, who wear the clothes you make all around the world?

Murtaza: I think the main message that I would like to share with the JACK & JONES consumer is that they are not only buying a piece of clothing, but they are investing into the lives of people far away in a positive manner. JACK & JONES is a truly great partner that is directly impacting communities around the world. I think that is something the global brotherhood should be very proud of.