The forest industry group Södra has now the unique solution to recycle fibers from blended fabrics on large scale. This solution is OnceMore® - the world’s first process for industrial scale recycling of blended textile waste. Indeed, most recycled fibers are not made from old and used textiles, they are made from production waste (pre-consumer) or in case of recycled polyester, PET bottles. But if something ever was easier said than done, it’s textile recycling. In fact, it’s one of the world’s biggest sustainability challenges. To recycle used textiles (post- consumer) is a science itself. Södra is not only the first one being able to recycle blended fabrics with high synthetic content but is one of the few to produce recycled viscose.

The pulp produced in the OnceMore® process consists of cellulose which originates from two sources – from recycled textiles and from wood from Södra’s sustainably managed forests. Today the recycled textiles mainly come from linen, towels and other textile products from hotels, hospitals and spas etc. The recycled textiles are certified.

The OnceMore® technology can handle blended materials with small stripes or logos, that is why hospitality industry and hospitals are a perfect source. Currently these textiles need be cotton blends with minimum 50% cotton content and mainly white/unbleached. Södra aims to be able to also recycle colored textiles in the future. Today they have the capacity to produce 6.000 tons (=24 million garments). The goal for 2025 is to process 25,000 tons of textile waste and offer a OnceMore® pulp based on our wood material and 50 percent recycled textile material.

The wood comes from responsible managed forests and is certified. This means that the harvest rates of the forests are based on recommendations issued by the Swedish Forest Agency and the Swedish University of Agricultural Sciences.

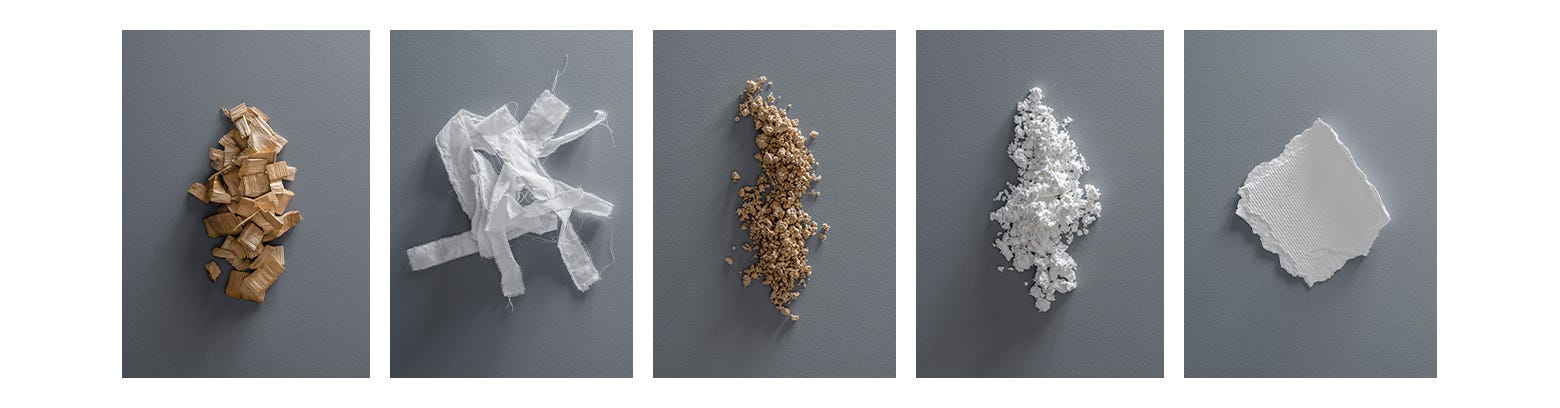

That is how it works:

• Blended textile waste, cotton, polyester, viscose and lyocell are collected.

• Cotton is separated from synthetic fibers.

• The cotton is chemically recycled.

• Wood pulp is derived from forests.

• The cellulose from the textiles is then combined with cellulose from wood.

• High quality dissolving pulp is produced.

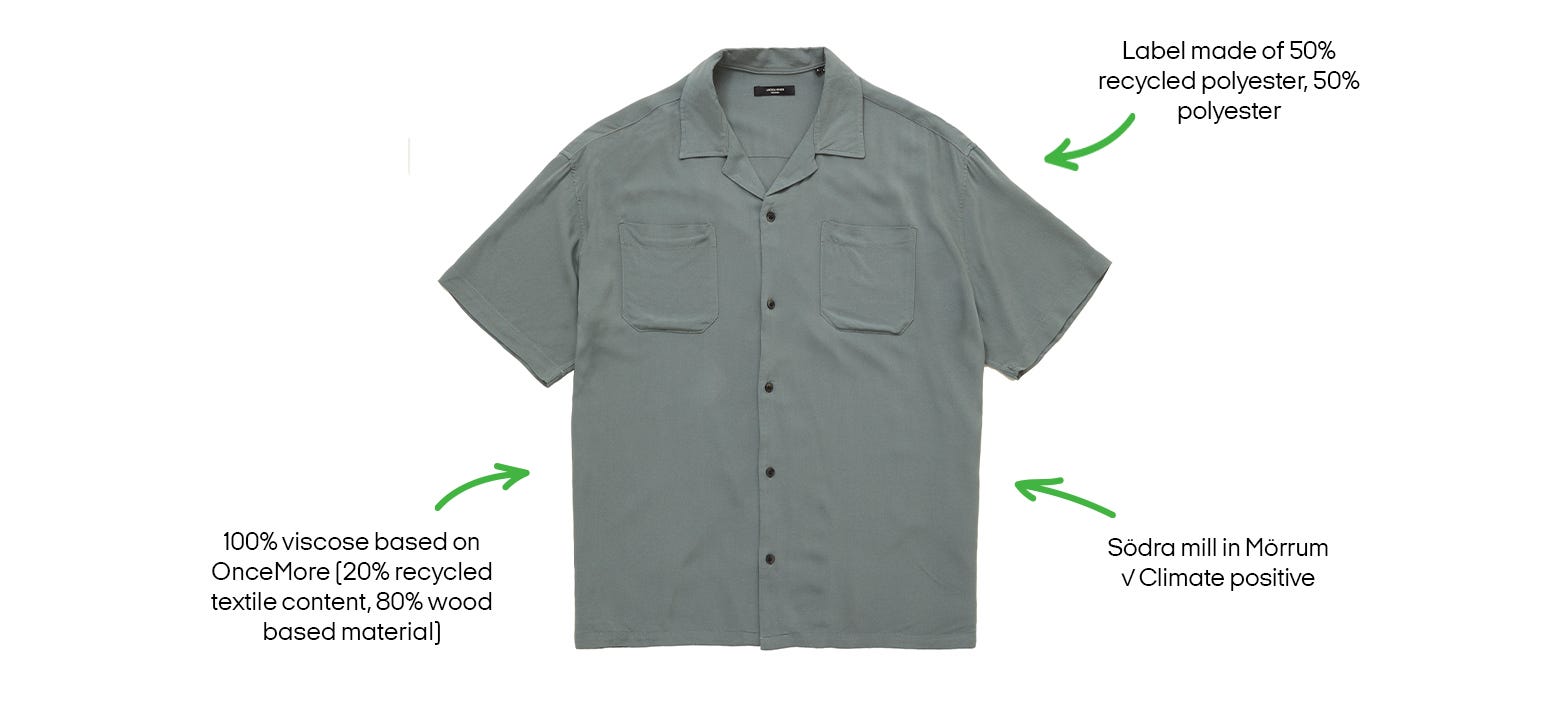

The OnceMore® pulp has an excellent processability with a high brightness, and it is equal to dissolving pulp for viscose or lyocell production when it comes to purity, quality and properties.

Södra’s industrial facilities are already today fossil-free and the company’s target is to achieve fossil-free transportation by 2030.

JACK&JONES has launched the ever first on market product with OnceMore® fibre in summer 2022. Since this successful start, we have launched another shirt program and knit program in 2023.